Coolant pipes from front to back

This is the plan:

The pipes will hang under the car, under the tunnel, hold on by brackets and exiting at the front just before the anti-sway bar. But

I am not sure about that yet, it might also go upwards somewhere where all the steering gear is. But there is not a lot of room, because

the steering rods need room to move.

The most interesting thing in this diagram is the way the coolant pipes are connected at the back. The connections on the radiator

and on the engine are swapped, because the engine is swapped around compared to its original position in the

Alfa Romeo. This means I have to cross the coolant pipes somewhere. I think the best place to do it is in the back. In the front there is not enough

room and it could compromise airflow.

I decided to make the two pipes exit at the same (left hand side) of the car. Then crossing the pipes can more easily be done around/above the gearbox.

edit 22-03-2008: I bought 3 exhaust pipes. These are all 3 metres long and have a 32 mm ( 1 1/4 inch) diameter.

These pipes have the right wall thicknes, not too thick and not too thin:

Now I have to rent a bender for a couple of days...

edit 14-04-2008: I rented a bender for the weekend:

The bender couldn't bend very tight turns, I couldn't bend at 90 degrees. I had to weld the sharp bends. This probably had something to

do with not having the entirely right templates for the bender. I used the 1'' template, and the pipes are 32 mm. It turned out the sizes on the template

were the inside diameter of the pipes. And it was meant for thick walled pipes. But it worked, sort of...

Pictures of the completed pipes later.

edit 16-04-2008:Here some quick pictures off the pipes:

From the radiator come two seperate pipes, and they are attached by a hose to the long pipes to the back. Those pipes go back and up to follow

the contour of the floorpan. Obivously, the pipes are hold on temporarely with wire, I still need to fabricate some brackets to hold them.

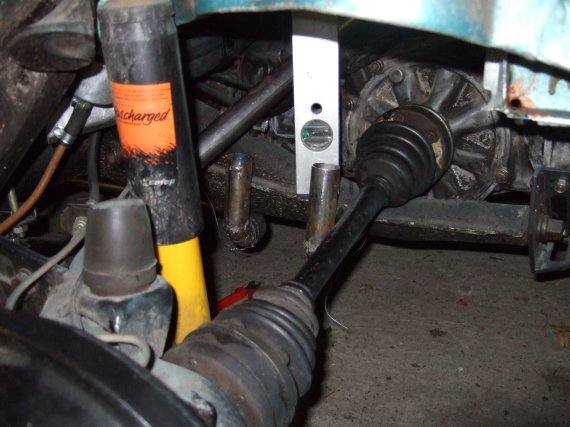

In the rear they both exit at the drivers side of the gearbox:

There the pipes that run over the engine will be attached. The pipe from the thermostat will be attached to the rear pipe. The pipe to the pump inlet will be attached to the front pipe.

These pipes aren't finished yet. The left one needs a sharper corner welded on to reach the thermostat. And the right one still needs sharp corners on both ends.

edit 20-04-2008: I finished the two pipes that go over the engine.

I added a bleed point to each pipe at the highest points of theses pipes.

It's a piece of metal fuel hose connector I welded in the pipe.

I also made a bracket to hold the two long pipes at the back.

It's made of a U bracket which is hold on to the frame with a clamp. To the U bracket I welded a side bar which has slots in it where the clamps that hold the pipes go through.

edit 30-04-2008: Finished the pipes and brackets:

I've got (besides the before mentioned bracket) two brackets that hold the pipes under the car. One in the front and one in the back. At first

I wanted to put a third bracket in the middle, but when I finished these two brackets I noticed that these brackets are holding the pipes sturdy

enough. I decided not to make a middle bracket.

I welded a little line on all pipe-ends and grinded it smooth. This should provide a "lip" to hold the rubber hoses on.

The rear support:

It's screwed onto the car under the back seat. Not shown in the picture is the bolt that screws through the bracket into the top piece to clamp the

pipes.

The front support is bolted to a hole I drilled in the floorpan in the piece under the master brake cylinder and on the other side of the tunnel in the same spot.

This bracket clamps the pipes with two bolts.

This afternoon I painted the pipes and brackets, tomorrow they are ready for (hopefully) final assembly.

edit 02-05-2008:All the pipes and brackets are painted and installed. The front:

Were the pipes exit next to the gearbox:

And the pipes that run over the engine:

I allready filled the system and did some test-drives! I noticed the hoses wanted to "walk" of the pipes, but luckily the little lips I welded on the ends of the pipes held them on! ALWAYS fabricate some sort of lip on the end of a coolant pipe! I pushed some of the hoses back on the pipe and added a second clamp just behind the lip.

The cooling seems to work well now, I've driven about 30 kilometers so far, with city and highway driving and the fans didn't switch on once!

edit 23-07-2008: I drove to a VW meeting in Germany, and when I returned home (after 150 kilometers) the return pipe started leaking. It turned out the short hose walked of the pipe. I probably made the right rear pipe too rigid and did not provide enough movement for the engine. I cut a piece out of the pipe and replaced it with flexible hose:

After changing this I drove 400 kilometers to a VW meeting in the south of the Netherlands (Budel). All was OK!

I mainly drove on highways and the average speed was around 130 km/h. It was fun looking at the other drivers who were passed by a VW beetle..

The car performed excellent!