Fitting rear fenders and apron

As you can see, the distribution covers from the Alfa engine are in the way of the apron and rear fender. I allready cut out a piece of the lip of the rear fender (standard width, in glassfiber), but that wasn't enough. The rear fender is still sitting to heigh:

I had to remove the top left bolt that holds the cover to the engine, and I had to cut a piece out of the cover:

Now it (barely) fits, this picture isn't entireley correct, it fits better than this:

I plan on making a cover around the distribution cover on the inside of the rear fender. This way no dirt can

enter the distribution system.

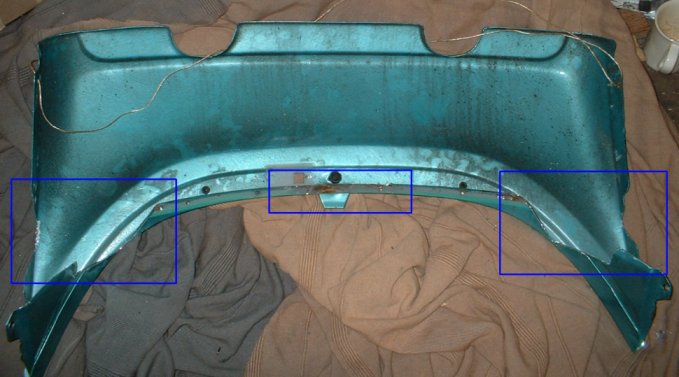

I also had to modify the rear apron to fit. Of course, I had to cut out a piece out of the sides, just like I did

to the fenders. But that wasn't all. On the inside I had to remove simular pieces and I had to remove the lip that

normally holds the engine-to-body-seal. I removed so much that the thing actually felt lighter, and I could

twist is more easily too afterwards.. But with the rear engine + rear apron supports (see: "design")I have in mind, this shouldn't

be a problem. It is a really tight fit here too. I probably will take some more out of the distribution covers to give

the apron some more clearance. And I will have to "cheat" a little bit. The rear apron is at a slightly smaller angle

than original. Here you can see where i made the cuts:

This how it looks when it was installed on the car:

I also tried the rear decklid on. There's going to be quite a large gap between the car and the decklid, but hey, that will only improve the venting of the engine compartment... :-)

I really like this rear decklid. It's made from glassfiber and I bought it very cheap on a meeting.

edit 20-03-2006: I put the alternator on, and discovered my decklid hit the alternator pully. I had to cut out a bigger piece behind the license plate (I already had put venting-holes in it). Now it looks like a monster... :

I also cut out another piece from the distribution covers, because the rear apron was still hitting it. It now looks like this:

It looks like I cut out to much, but the distribution belt is still covered by the cover, so it can't hit the rear apron.

Because I remove the top left attachment poin of the covers, I had to create an alternative. I used a piece of threaded bar

and put a spacer inside the covers, you can see the end of the threaded bar with a nut on it in the picture.

edit 25-03-2006:

I wasn't satisfied with the amount of room between the rear apron and the engine. Then somebody on the keversite.com forum

suggested to file out the rear gearbox mount, so the gearbox (and thus the engine) will sit lower.

This is my rear gearbox mount:

And this is it after filing the holes for the bolts:

I won 6 millimeters with this. That may not sound like much, but as it is a really tight fit, this is a very welcome 6 millimeters.

edit 06-04-2006: I bolted the left rear fender and the rear apron back on, so I can see the results of filing out the rear mount.

Before: |

After: |

Before: |

After: |

edit 23-09-2006: I can't get the tripple pully of the engine. I tried with a cheater bar and it didn't do anything! I didn't want to put to much force on it because I blocked the flywheel with a crowbar. This meant all the force is put on the crankshaft. That can't be good, so I left it on. But this meant I had to cut out another piece out of the rear apron:

Now I want to create the rear apron supporting brackets. But for that I first had to put on the rear decklid. Then I can see how much I can raise the rear of the apron.

It starting to look like a complete beetle again...

edit 10-04-2007: I made two brackets to hold the rear engine brace (see other to-do topic). On these brackets I welded supports for the rear apron. I attached the rear apron to these little brackets with a piece of 6 mm threaded bar:

Now I can adjust the rear apron, it can be moved backwards. This gave me some more room between the rear apron and the distribution belt covers. This is a test-fit, I will secure the adjustment with a extra nut after I painted it all and re-installed it.

edit 22-04-2007: Made a little cover for the distribution cover on the drivers side.